Quality Policy

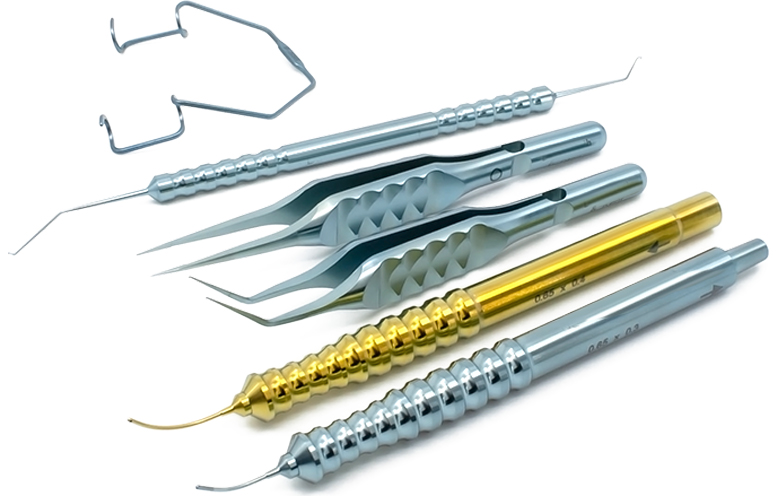

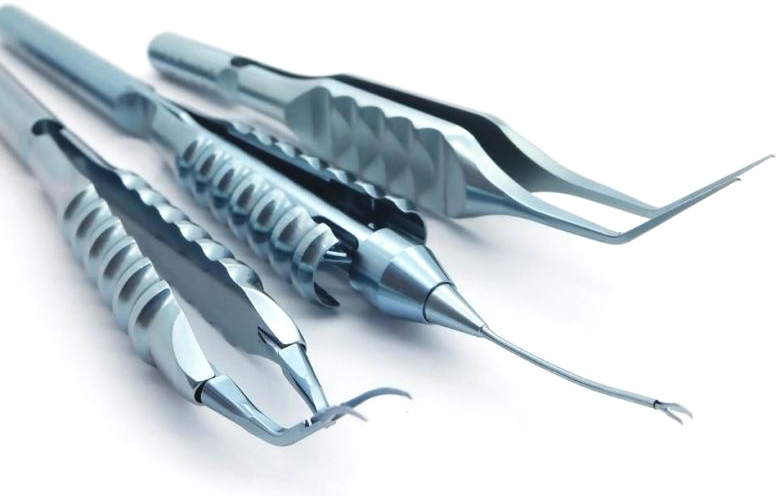

At Kara Instruments, we are committed to delivering superior quality dental and surgical instruments that meet and exceed the expectations of our customers. Our relentless pursuit of excellence and dedication to continuous improvement are at the core of our quality policy. We strive to ensure that our instruments meet the highest standards of precision, performance, and reliability, while adhering to applicable regulatory requirements.

Our quality policy is guided by the following principles:

Customer Satisfaction: We prioritize customer satisfaction and strive to understand and meet our customers' evolving needs. By actively engaging with our customers, we seek feedback and insights to continuously improve our instruments, services, and processes. Our aim is to provide exceptional value and exceed customer expectations at every touchpoint.

Commitment to Quality: We are dedicated to maintaining the highest level of quality in all aspects of our operations. Our skilled craftsmen and technicians meticulously design, manufacture, and test our instruments using advanced techniques, state-of-the-art equipment, and the finest materials. We have implemented robust quality control measures throughout our manufacturing processes to ensure consistent product excellence.

Continuous Improvement: We believe in the power of continuous improvement to drive growth and enhance customer satisfaction. We foster a culture of innovation and learning, encouraging all our employees to contribute to the identification and implementation of improvement opportunities. Through regular monitoring, analysis, and review of our processes, we continually seek ways to enhance quality, efficiency, and effectiveness.

Regulatory Compliance: We are committed to upholding all relevant regulatory requirements and standards. Our quality management system is designed to ensure compliance with applicable regulations, certifications, and industry best practices. We regularly review and update our processes to maintain compliance and continually improve our quality system.

Employee Empowerment and Development: We recognize that our employees are our most valuable asset. We provide a safe and inclusive work environment that promotes teamwork, open communication, and personal growth. We invest in the training and development of our employees, empowering them to contribute to our quality objectives and fostering a culture of accountability and excellence.

Supplier Partnerships: We establish strategic partnerships with reliable suppliers who share our commitment to quality and integrity. We work closely with our suppliers to ensure the consistent delivery of high-quality materials and components that meet our specifications and standards. By maintaining strong supplier relationships, we can continually improve the quality of our instruments.

Environmental Responsibility: We are dedicated to minimizing our environmental impact. We strive to conserve resources, reduce waste generation, and implement sustainable practices throughout our operations. Our commitment to environmental responsibility extends to responsible sourcing, waste management, and energy conservation.

This quality policy serves as the foundation of our organization and is regularly reviewed for continued suitability and effectiveness. We are committed to communicating and implementing this policy at all levels of our organization, ensuring that it is understood, shared, and practiced by every member of the Kara Instruments team.

CEO, Kara Instruments

QUALITY MANAGEMENT SYSTEM

Our significant manufacturing steps are being described here-under briefly:

Interested in distribution?

Need help locating an instrument?

Need to place an order?